Definition and safety classes for safety knives

What is a Safety Knife:

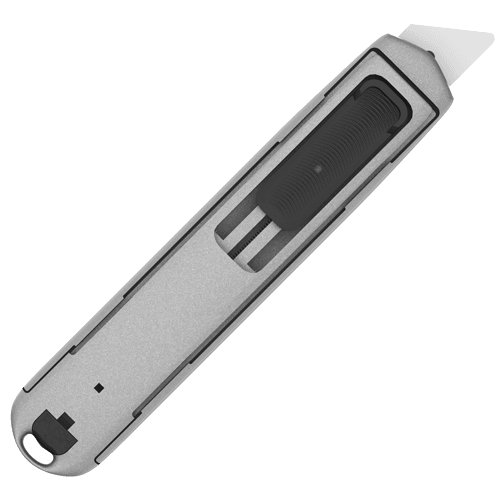

A safety knife is a spring-loaded knife with a self-retracting blade, primarily used to open boxes and packaging. Used in a number of different industries, safety knives help to greatly reduce the risk of knife-related injuries in the workplace.

Most safety cutters feature a concealed blade, which can be pushed into a working position with the slider on the side. Once in a working position, the safety knife can effectively cut through cardboard, plastic, and other types of packaging. However, once the slider is released, the safety blade automatically retracts, providing increased protection for the employee, compared to the use of a standard knife.

Safety knives are an essential part of occupational health and safety, helping to prevent injuries in the workplace, from minor cuts to the more severe. It’s important to ensure that employees are able to carry out their roles with as little risk as possible, making safety cutters a solid investment.

The four Safety Classes for Safety Knives:

Safety knives are versatile work tools that can be used for cutting a variety of different materials, such as plastics, paper, cardboard, foils, and much more.

The design of a safety knife usually consists of a body, a blade, and a button or switch. The blade can come out of the body of the knife by means of an appropriate mechanism or be completely concealed to make cutting injuries as good as impossible.

There are four safety classes for safety knives that can be considered:

Safety Class 1: Simple Craft Knife or Carpet Knife

Safety Class 1 provides little protection. In this class, the simple carpet knives and craft knives are summarized.

In order to use these types of safety cutters, it is necessary to push out the actual blade. The blades on these knives are often made of plastic and have a predetermined breaking point, meaning that the blade will “snap-off” when it has become dull.

Unfortunately, the use of these cutting tools often leads to

accidents. The “snap-off” blades can also break involuntarily during the

cutting process and thus pose a health and safety risk. These knives also do

not have a spring bearing on the blade, which automatically pulls the blade

back into the shaft. Therefore, there is a danger that blades may be

left lying around the workplace, forming another potential safety hazard.

Safety Class 2: Safety Cutter with Automatic Blade Retraction – AutoSlide

Safety Class 2 is the AutoSlide safety cutter. This range/product ensures that the safety knife blades are retracted automatically after the cutting process. The spring tension in these cutters ensures that the blade is pulled in as soon as the user releases their finger or thumb finger from the slider. This type of safety knife provides increased protection for both the user and the material.

Safety Class 3: Safety Cutter with Fully Automatic Blade Retraction – AutoSafe

The next class is safety knives with fully automatic blade retraction.

These types of safety knives help to greatly reduce the risk of accidents or injuries, due to their unique feature. As soon as the cutting process is interrupted or when the blade disengages from the material, it is automatically retracted back into the shaft.

This helps prevent injuries that may occur without the knife being used in action. That is why the AutoSafe safety knives are a class above the AutoSlide and other simple safety knives in regard to protection.

Safety Class 4: Safety Knife with a Concealed Blade

The highest security is provided by safety knives with concealed blades.

Due to the design, only a small area of the blade is released, while the rest is sheathed to avoid contact with the user. The hook design also stops the small area of blade coming into contact with the fingers of the user, making it almost impossible for the user to injure themselves during the cutting process.

There are different versions of safety blades with a hidden blade. These range from very simple disposable safety knives to ones with interchangeable hidden blades (such as our GR8 range of safety knives) to food grade safety knives that are metal detectable.

Employee Safety and Material Protection for Your Company:

The safety of your employees should be your number one priority, as according to HSE (The Health and Safety Executive) reports 3.9 million working days were lost due to non-fatal workplace injuries in 2018. This resulted in annual costs of over £15 billion to the UK economy due to work related injuries.

If you are not sure which type of safety knife is best for your purpose, please feel free to contact a helpful and friendly member of our team, who will be happy to help.

Back to Top